Metal Expansion Joints

Salient Features

- State-Of-Art Manufacturing Facility

- Wide Product Range

- In-House Design, Inspection And Testing Facilities

- Proven Track Records

- Good Technical Expertise

Industrial Applications

- Energy

- Engineering Companies

- LNG, LPG

- Refineries & Petrochemicals

- Aerospace

- Government / Military

- Cryogenic

- Engines & Turbines

- Air conditioning / Air Heating

- Aircraft Engines and Engine Parts

- Cement Plants

- Co-generation

- Electrical Industrial Apparatus

- Food Industries

- Gas compression equipment

- Heavy Construction

- Hydraulic Plants

- Furnaces & Ovens

- Iron & Steel Foundries

- Mining

- Metal Working

- Metal Mining

- Natural Gas

- Nuclear

- Offshore

- Paper Mills

- Pharmaceuticals

- Railroad Equipment

- Ship Building

- Steel Mills

- Steel Works & Blast Furnaces

- Water Transportaion

Type of Material

- Stainless Steel-Type 300 Austentic Series

- Nickel 200 (ASTM B162-200)

- Alloy 400 (ASTM B127-400)

- Alloy 600 (ASTM B168-600)

- Alloy 625 Gr.1 (ASTM B443-625)

- Alloy 625 LCF (ASTM B443-625 LCF)

- Alloy 800 (ASTM B409-800)

- Alloy 825 (ASTM B424-825)

- Hastelloy (C22 & C276)

- Titanium (ASTM Gr.2)

- Duplex, Super Duplex Stainless Steel

Product Range

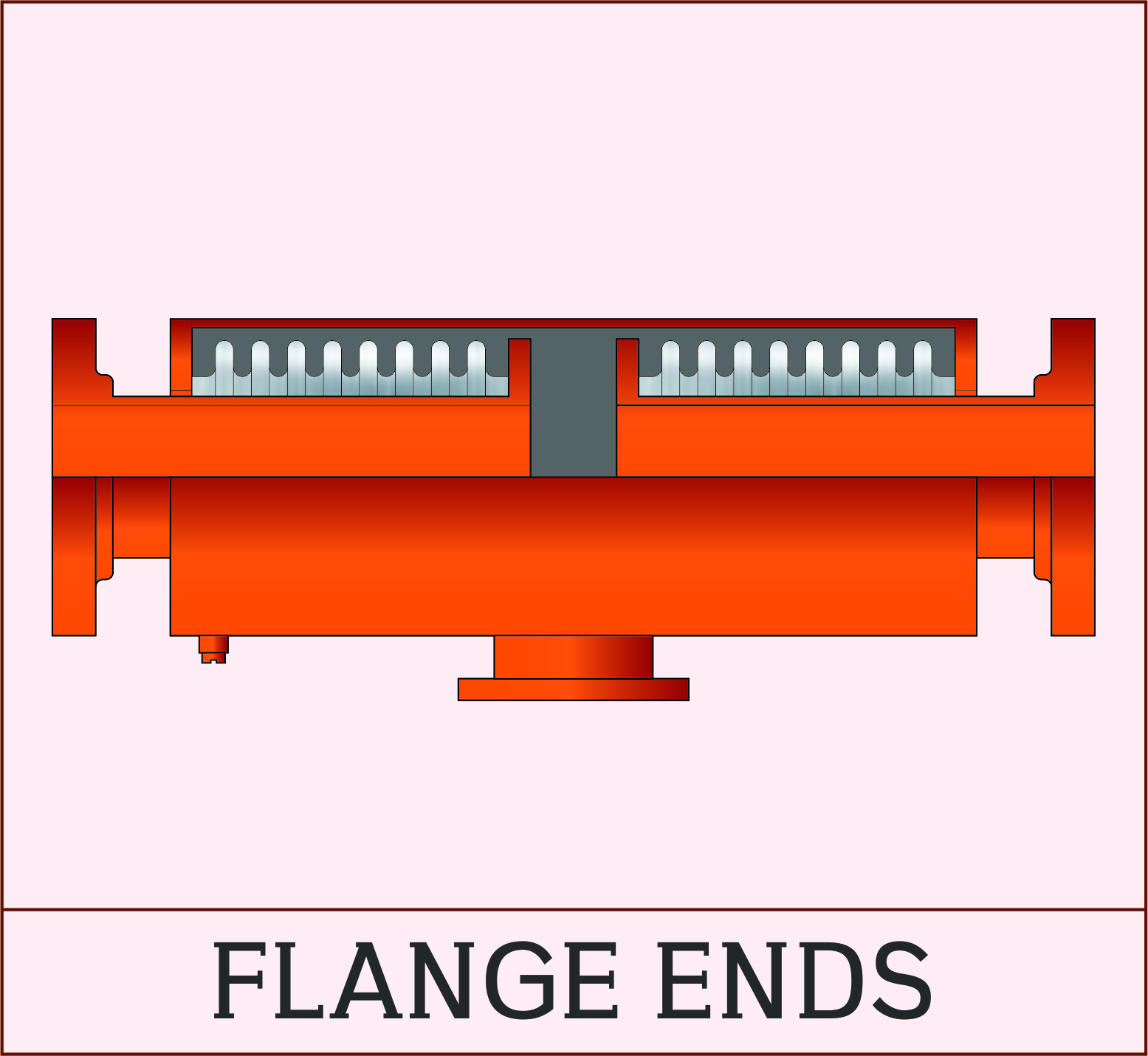

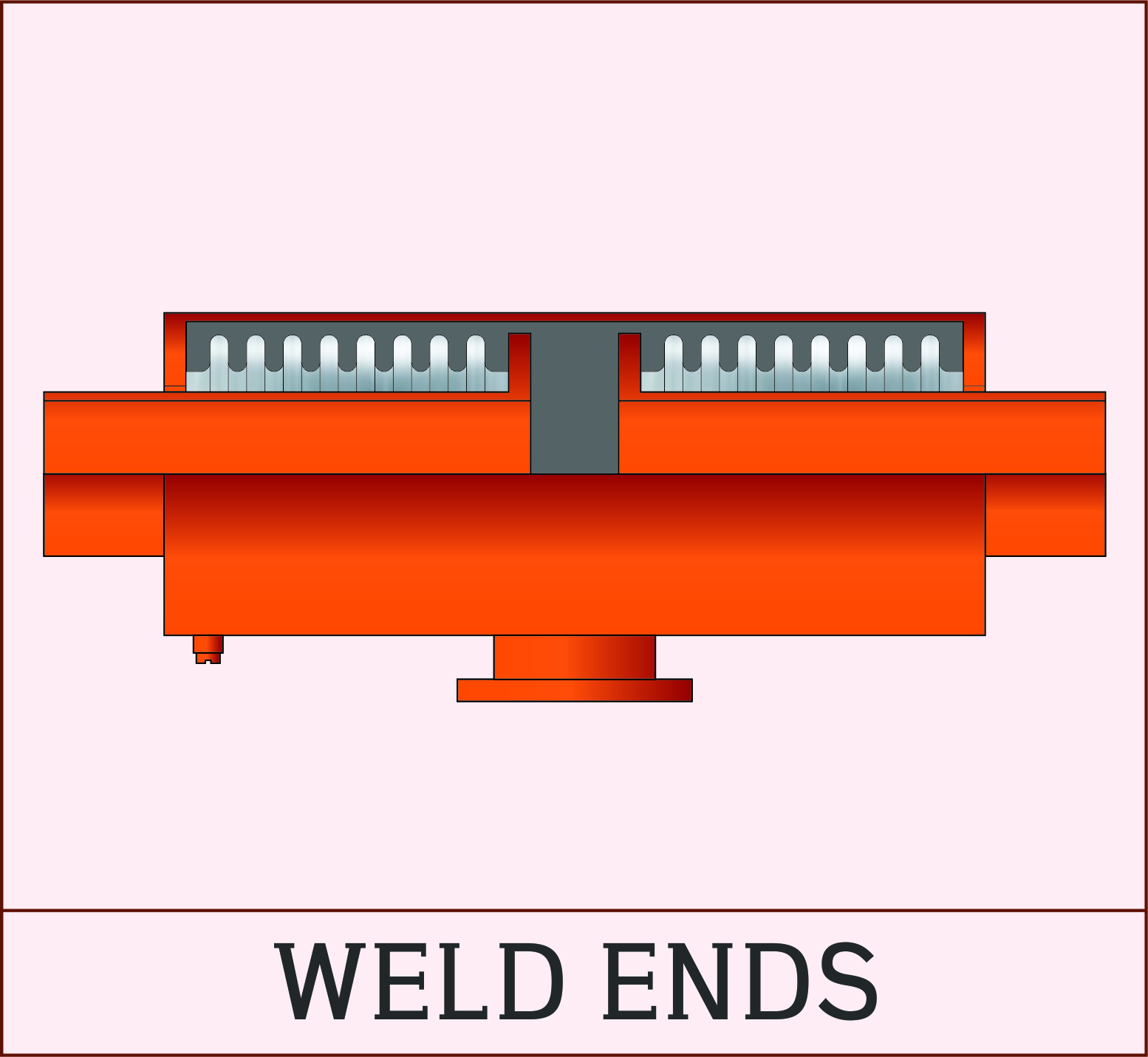

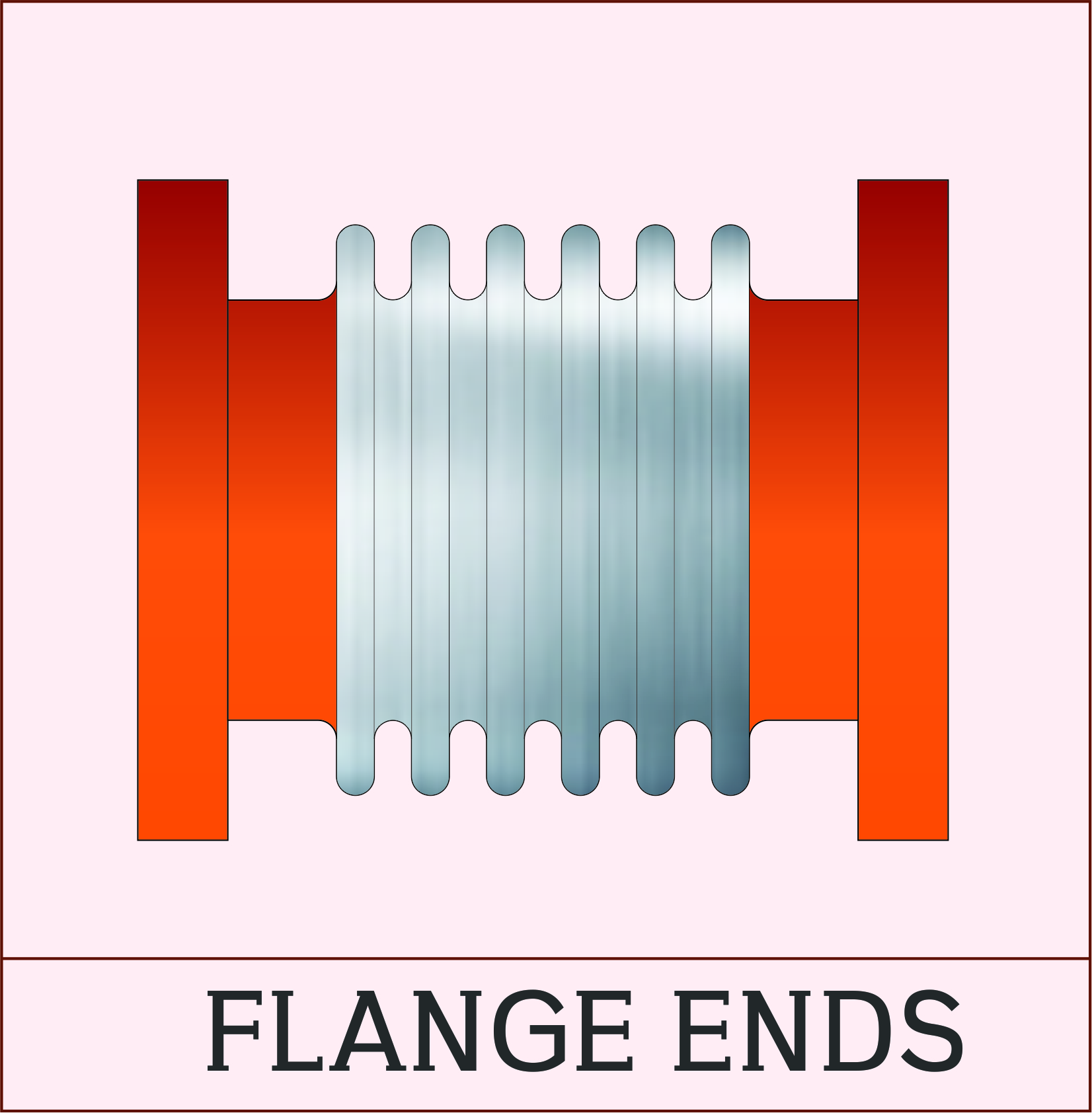

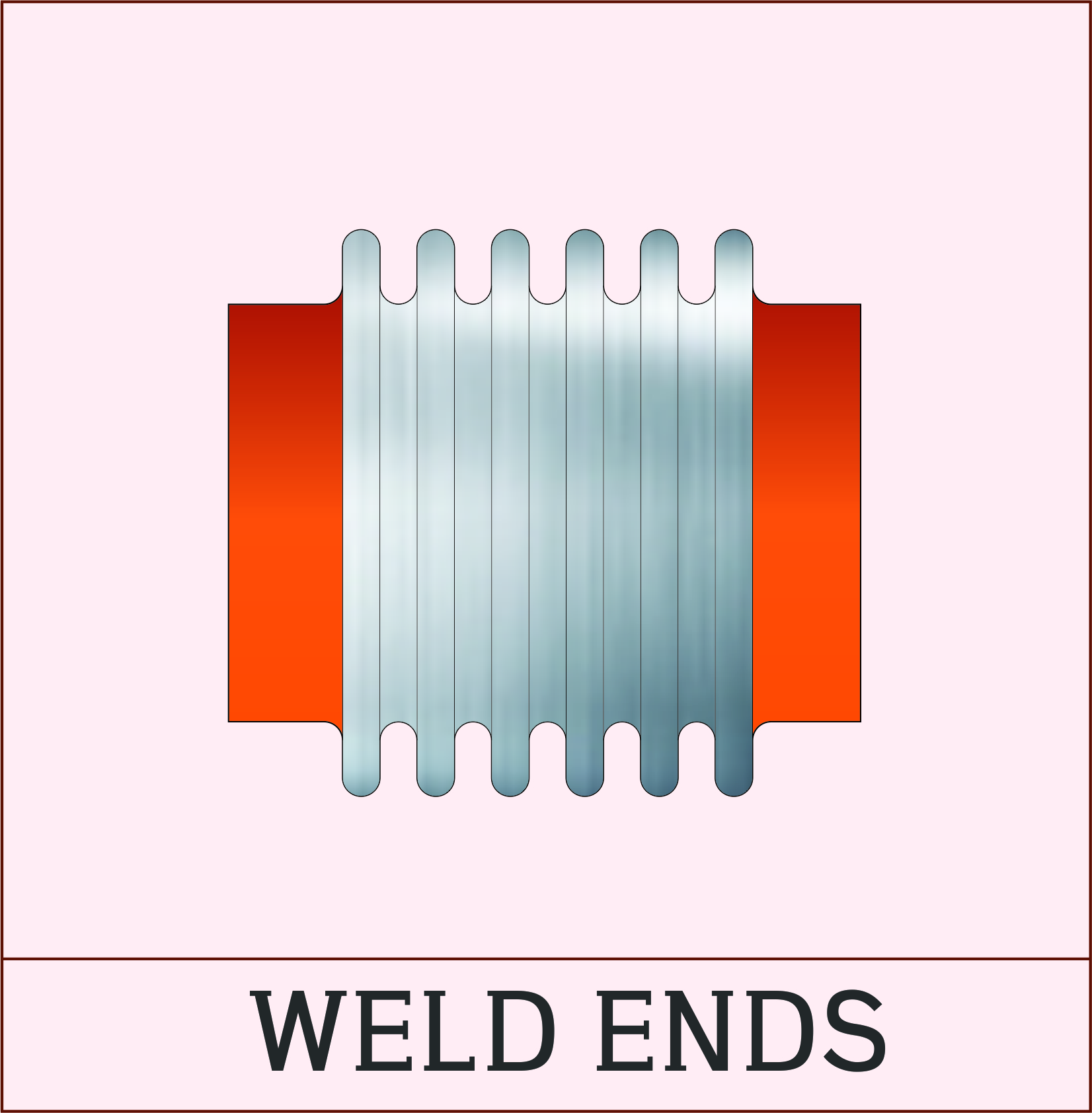

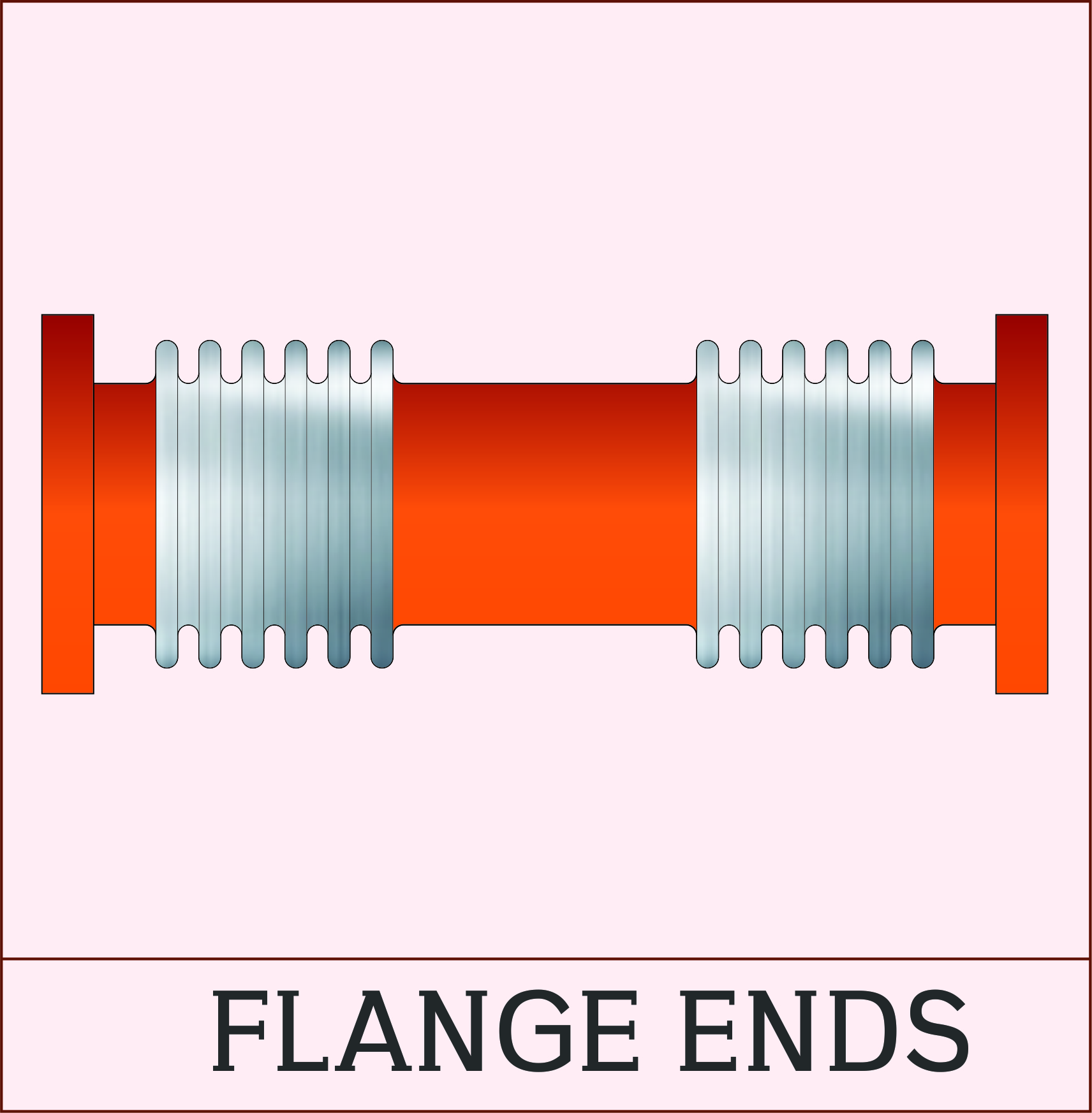

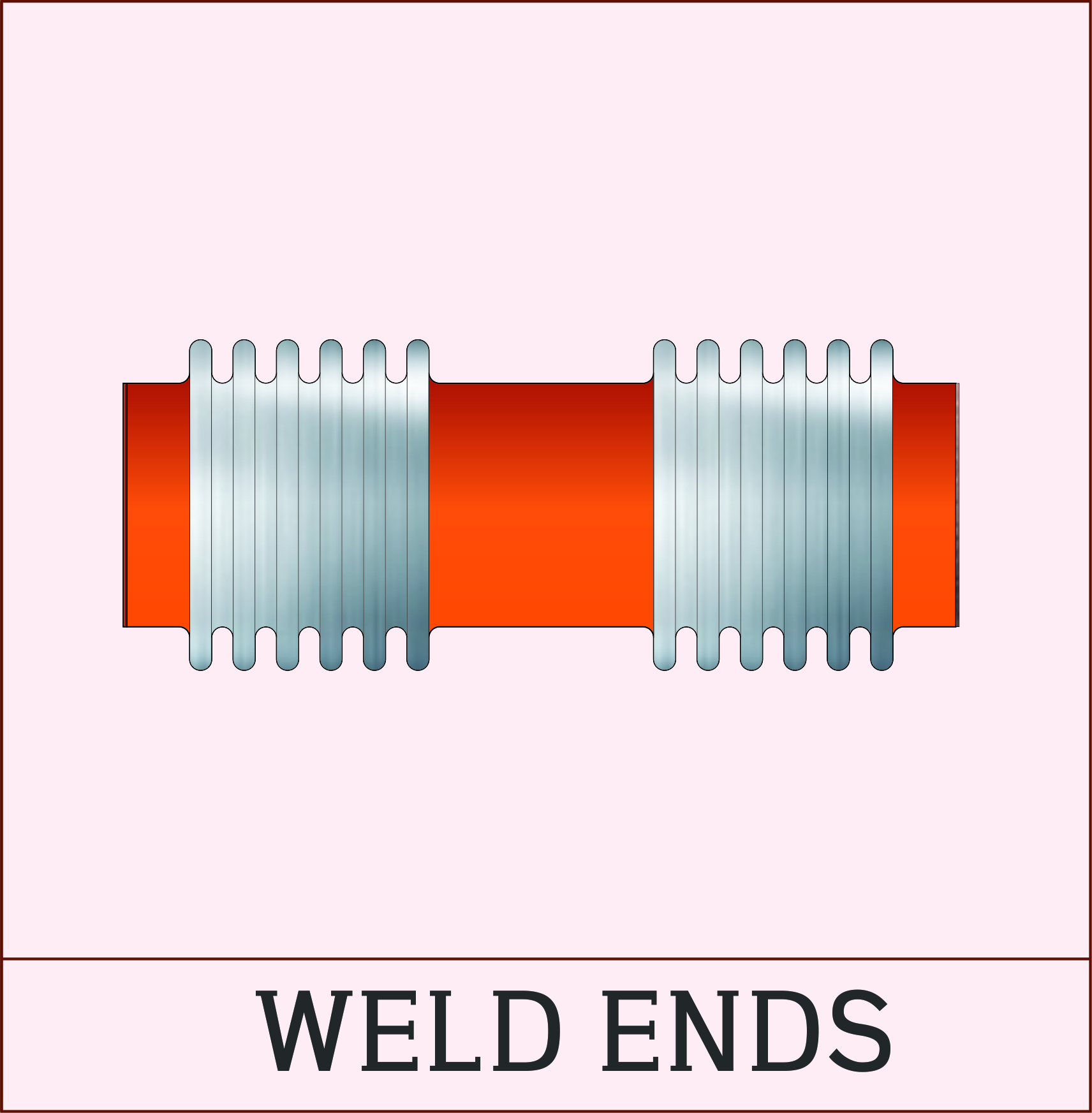

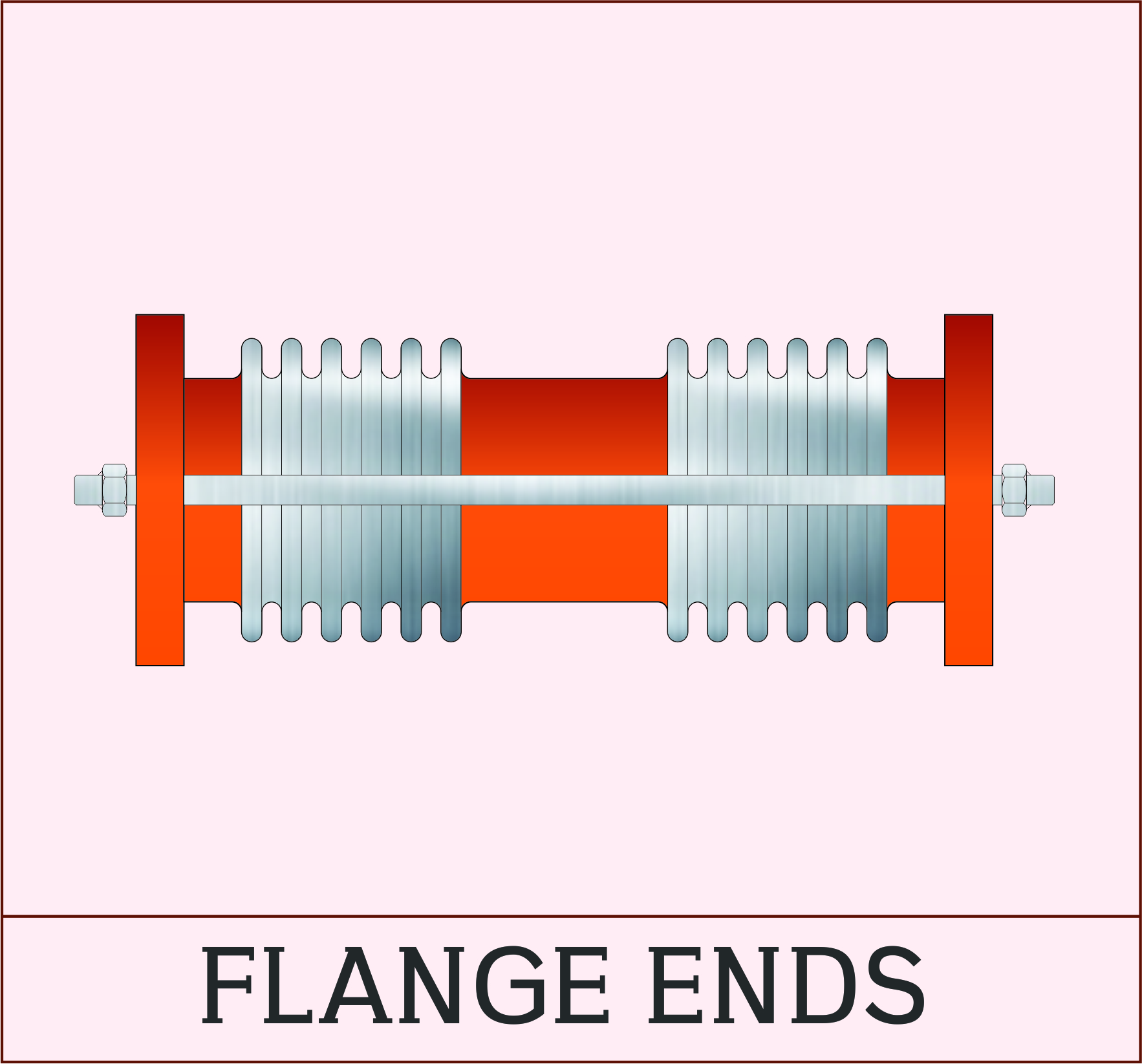

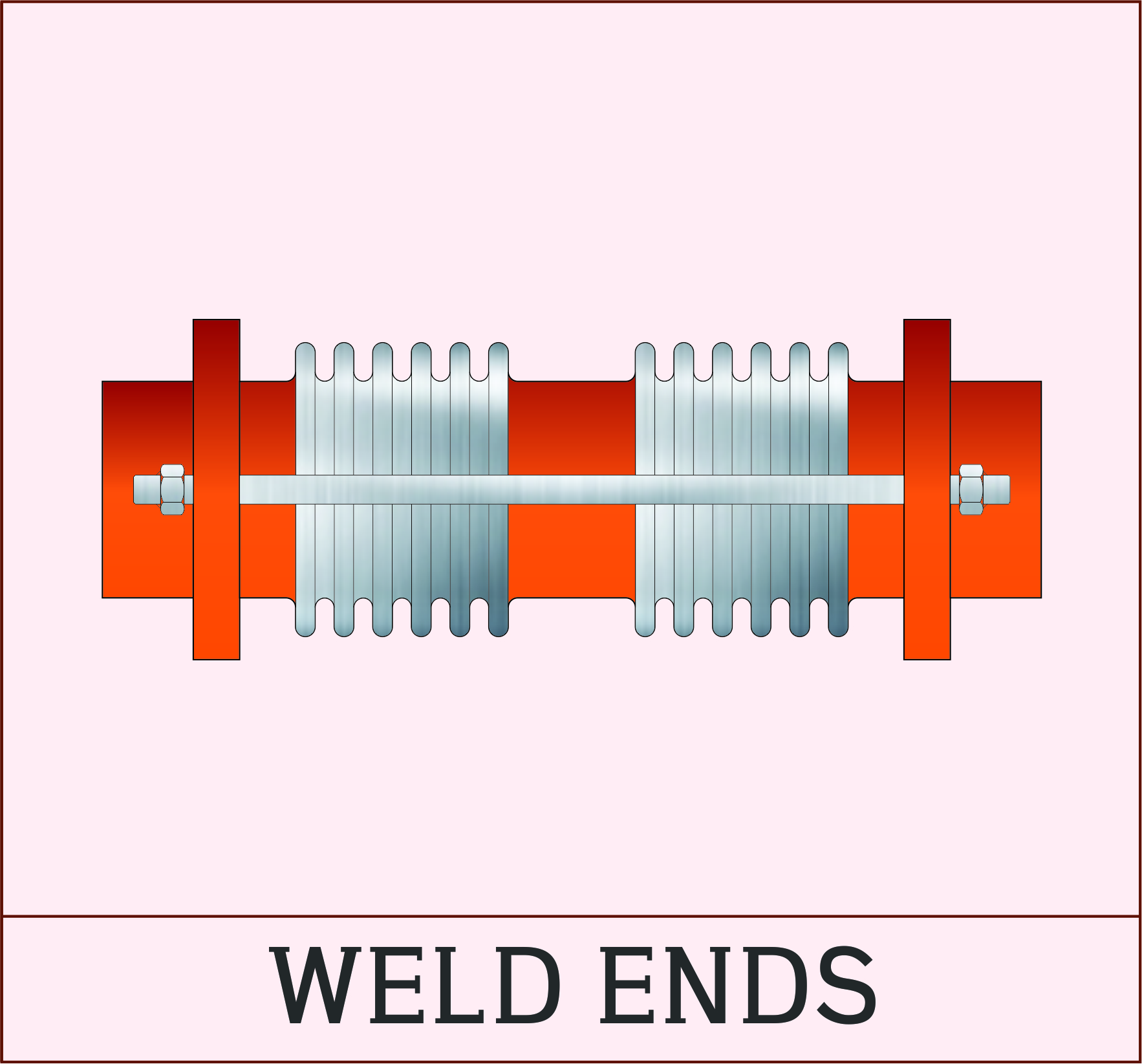

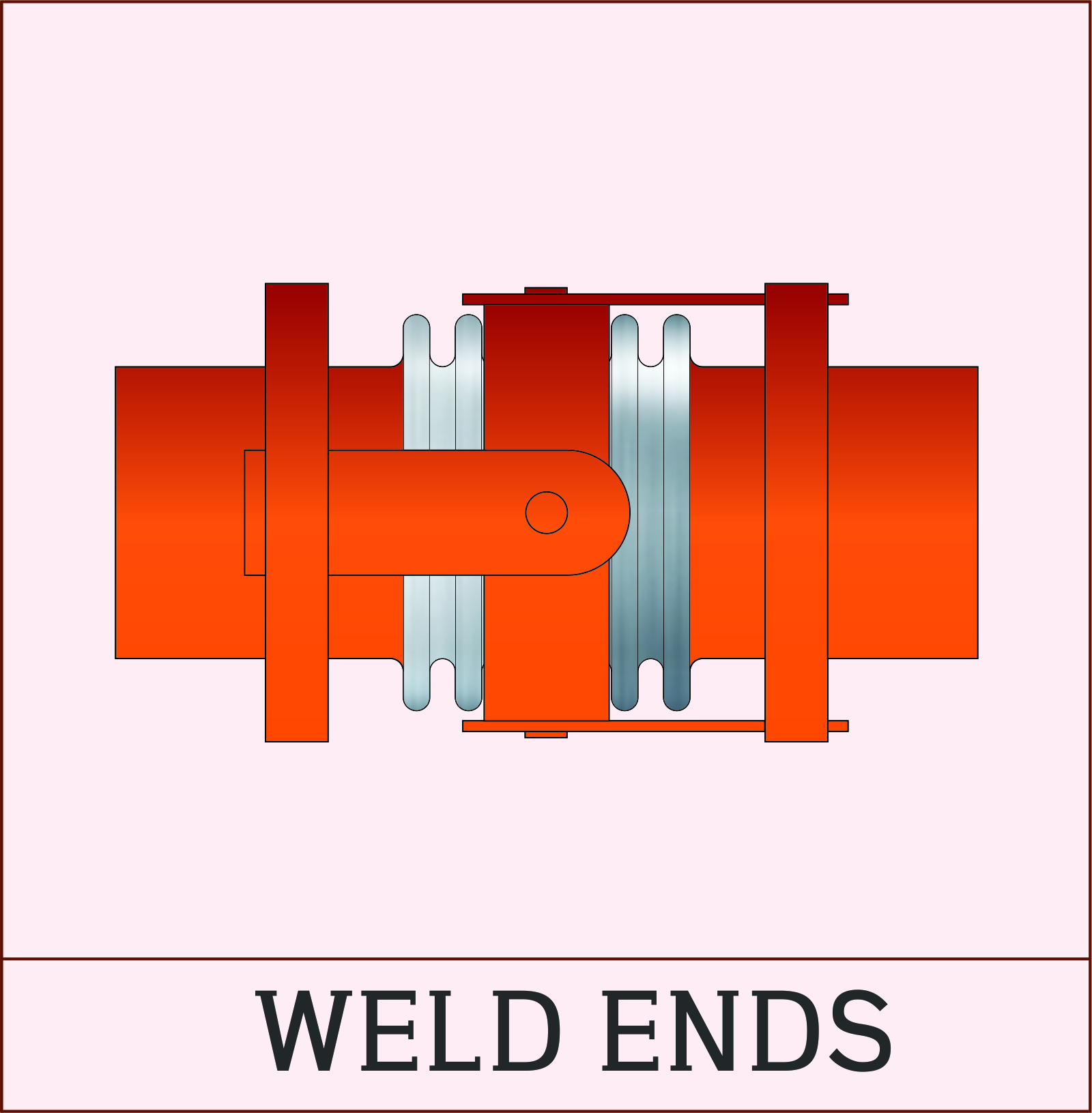

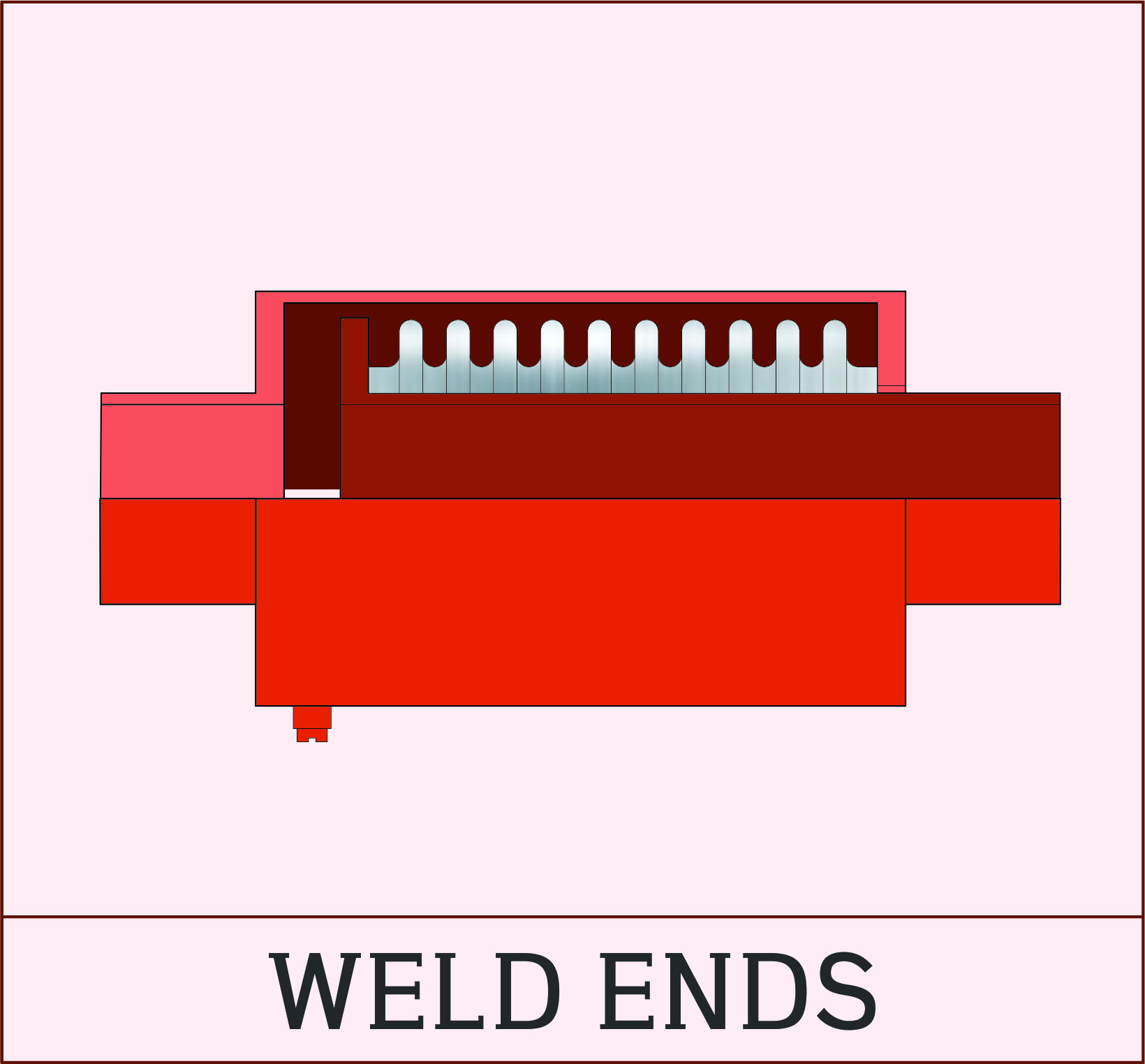

The simplest type of expansion joint consists of a single bellows element welded to end fittings, normally flange or pipie ends.The single bellows can absorb small amounts of axial, lateral and angular movement with ease, but adequate anchors and guides must be provided.

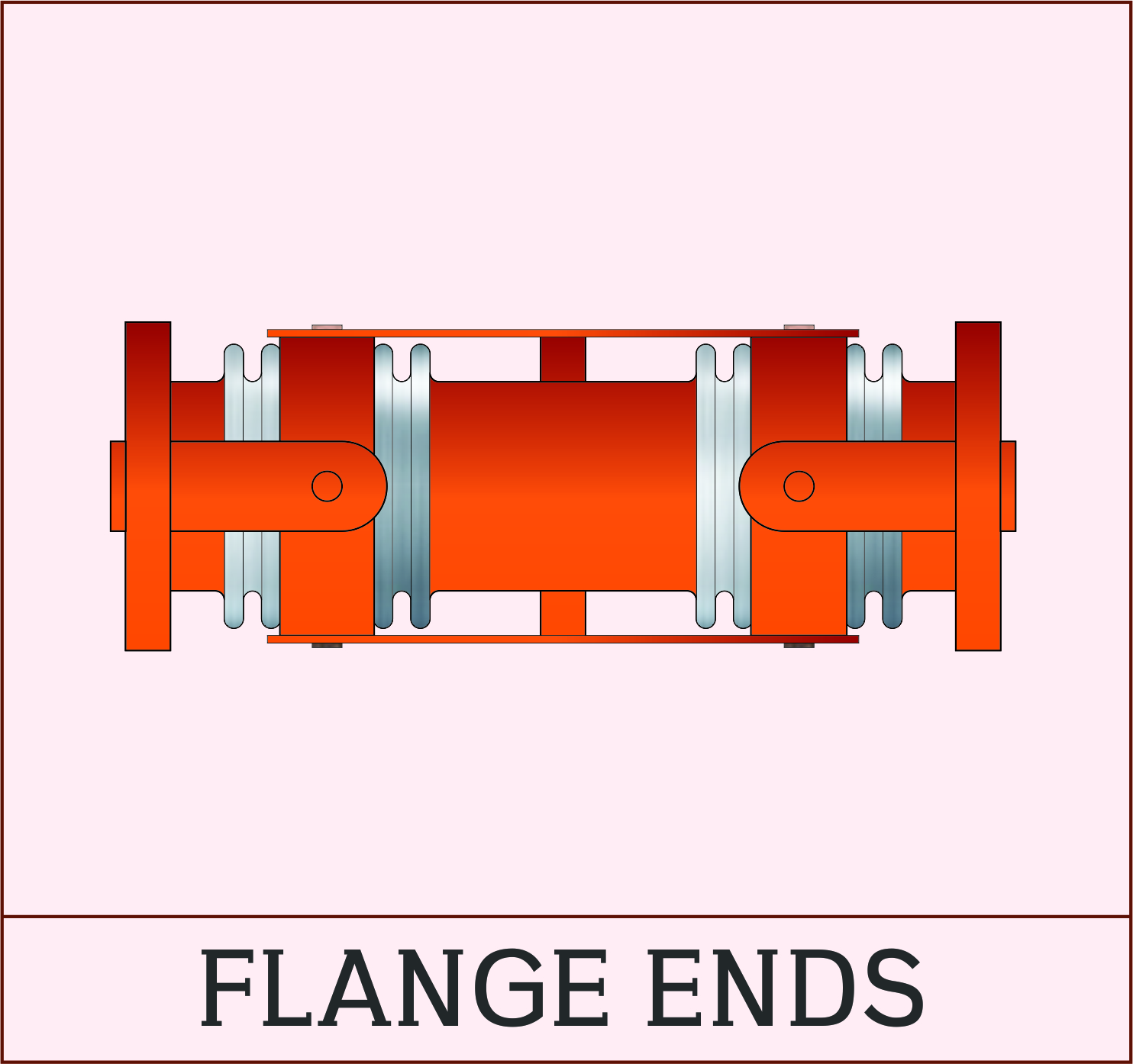

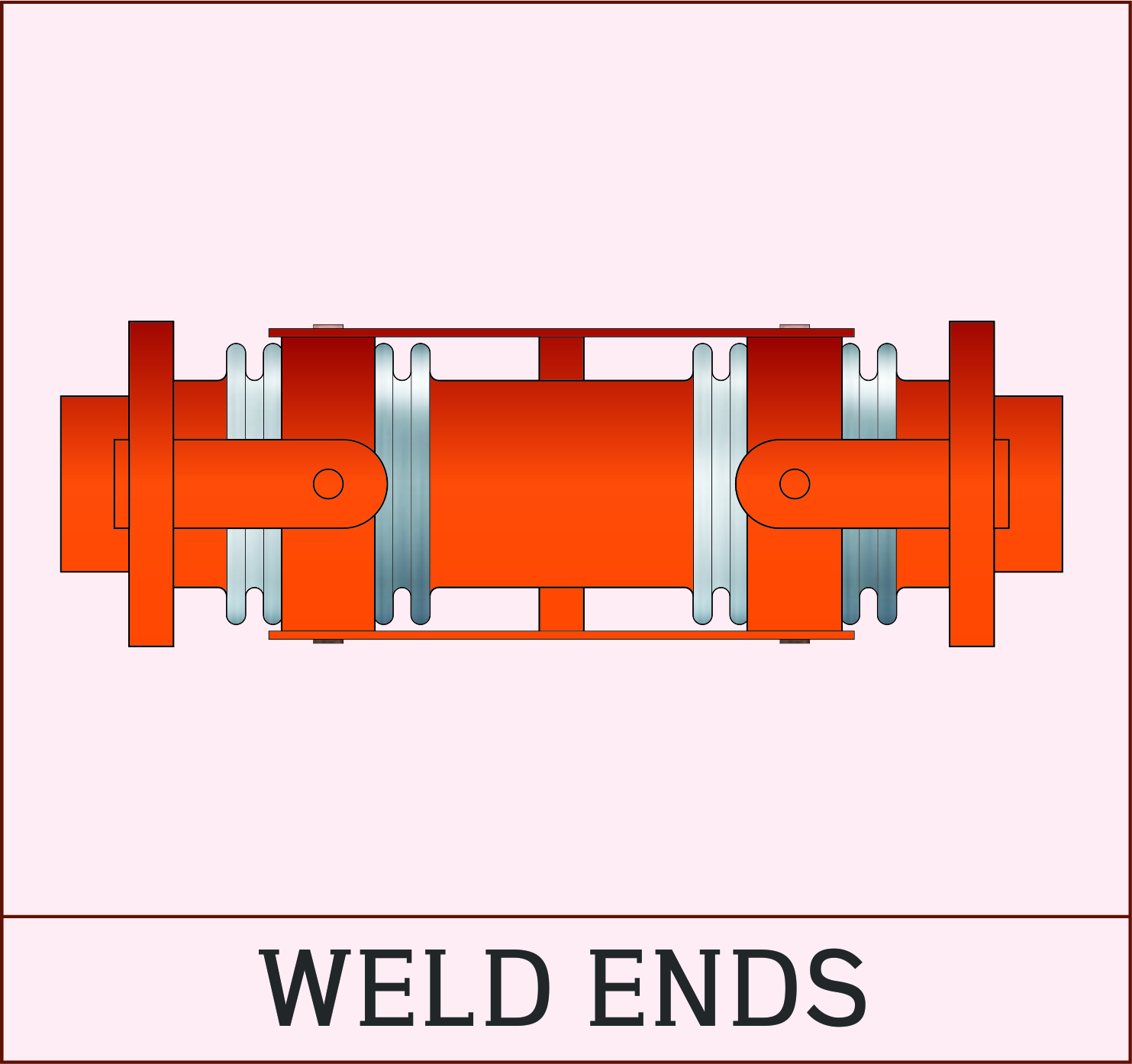

This assembly consists of two bellows connected by a center spool piece with flange or pipe ends. The universal arrangement allows greater axial, lateral and angular movements than a single bellows assembly. Increasing the center spool length produces increased movement capability.like the single bellows, adequate anchors and guides must be provided.

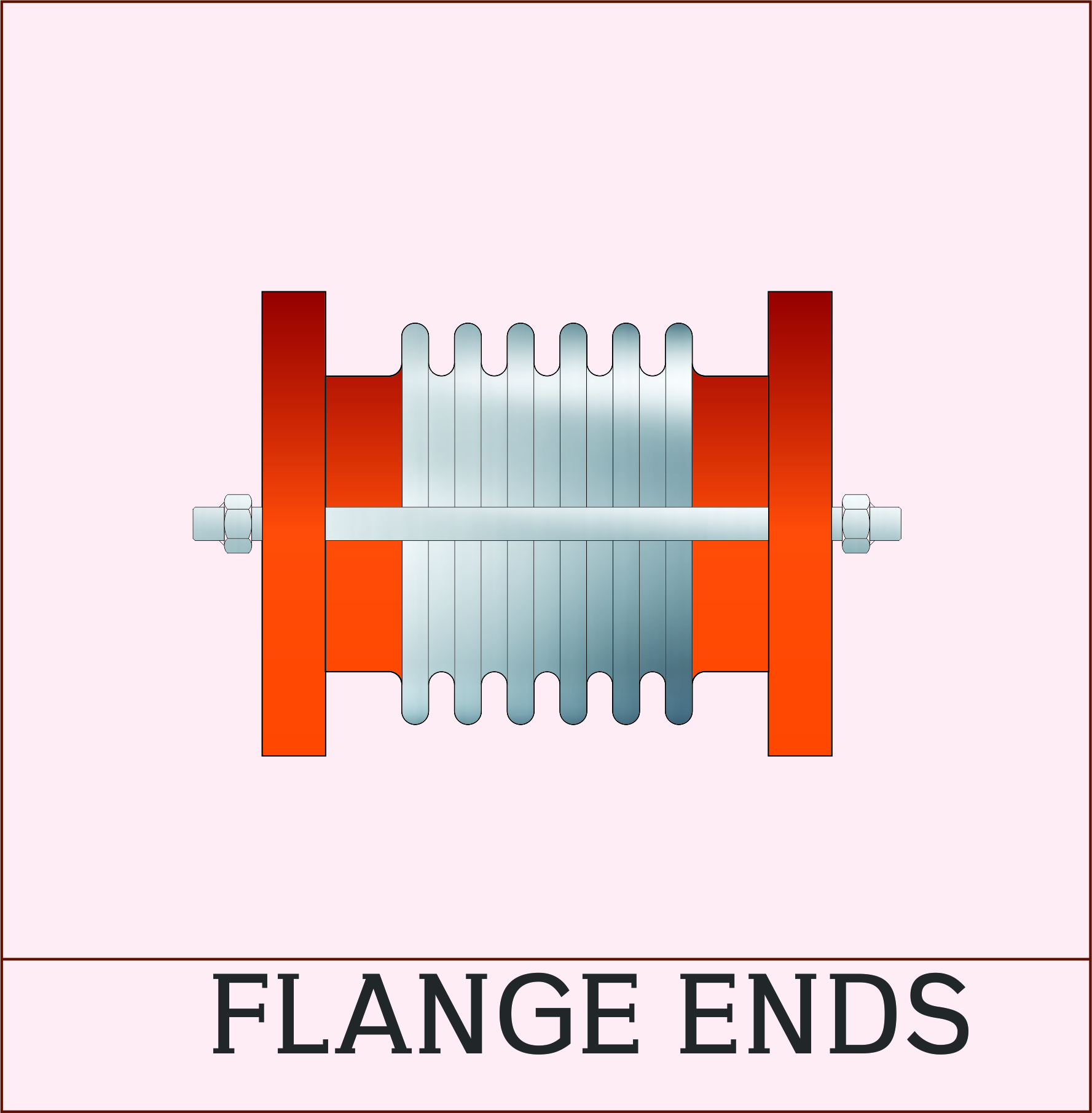

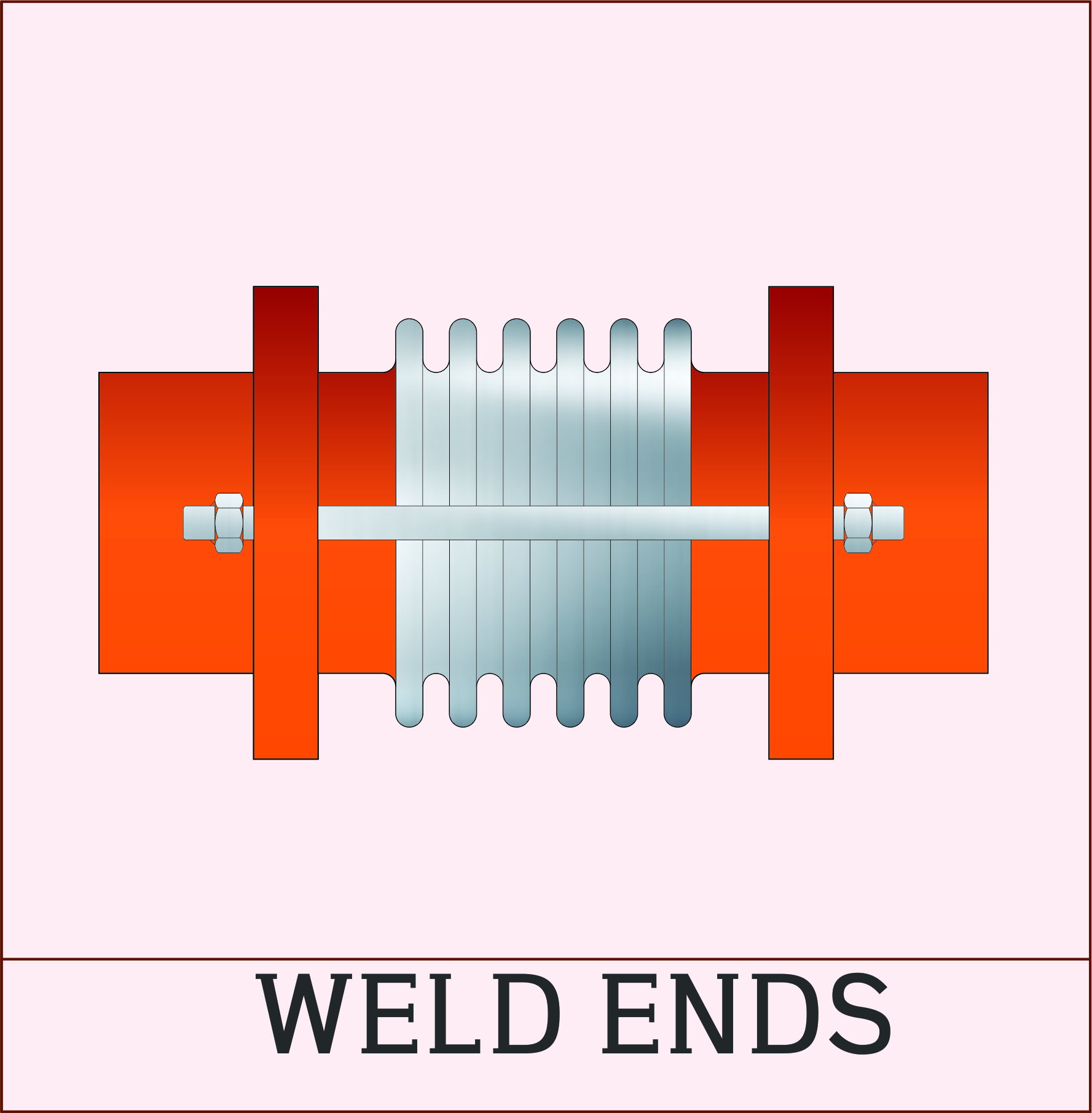

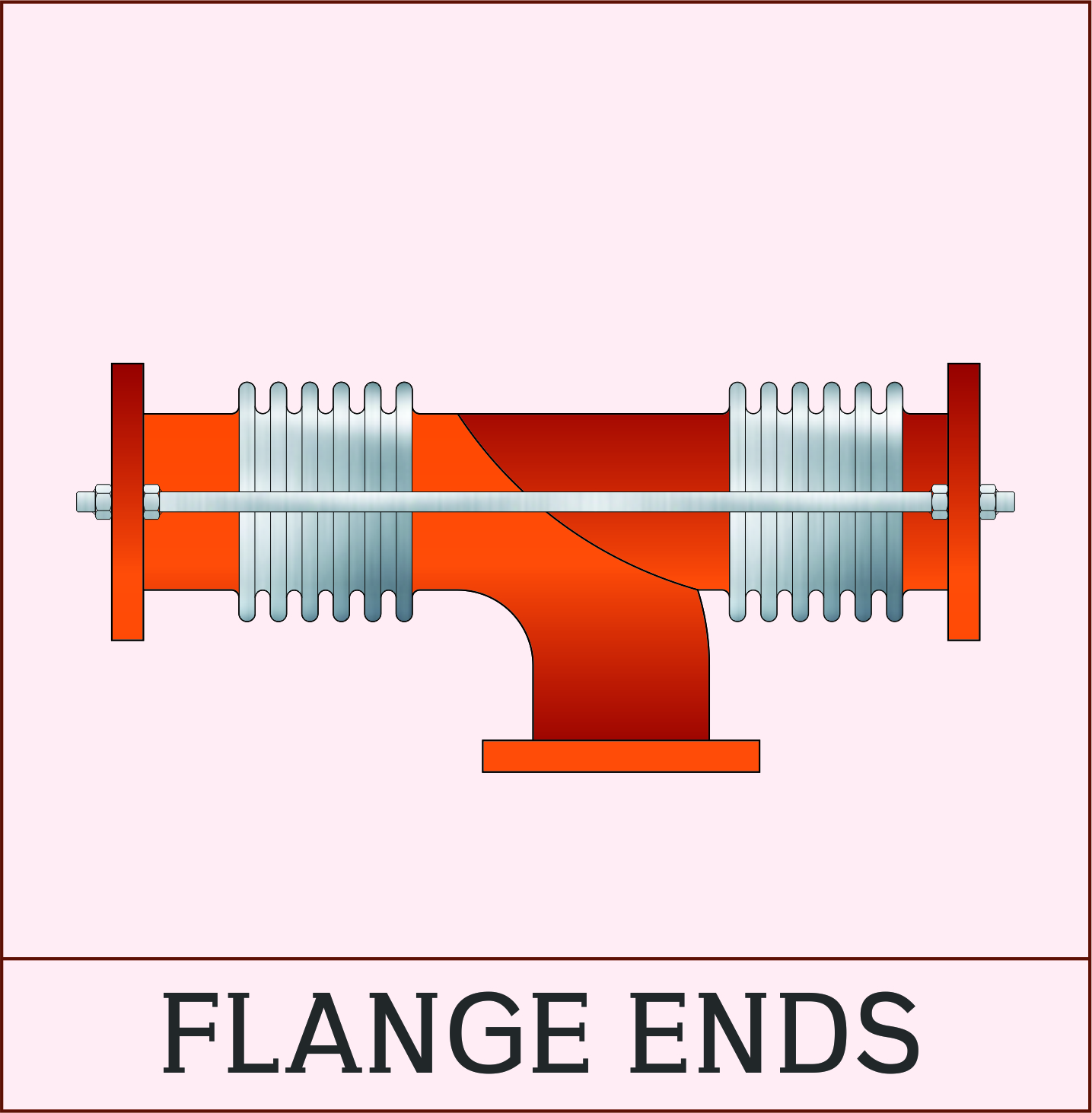

The addition of tie rods to a single bellows assembly adds design flexibility to a piping systm. The tie rods are attached to the pipe or flange with lugs that carry the pressure thrust of the system, eliminating the need for main anchors. With the assembly tied the ability to absorb axial growth is lost. only lateral and angular movement can be absorbed with the tied expansion joint.

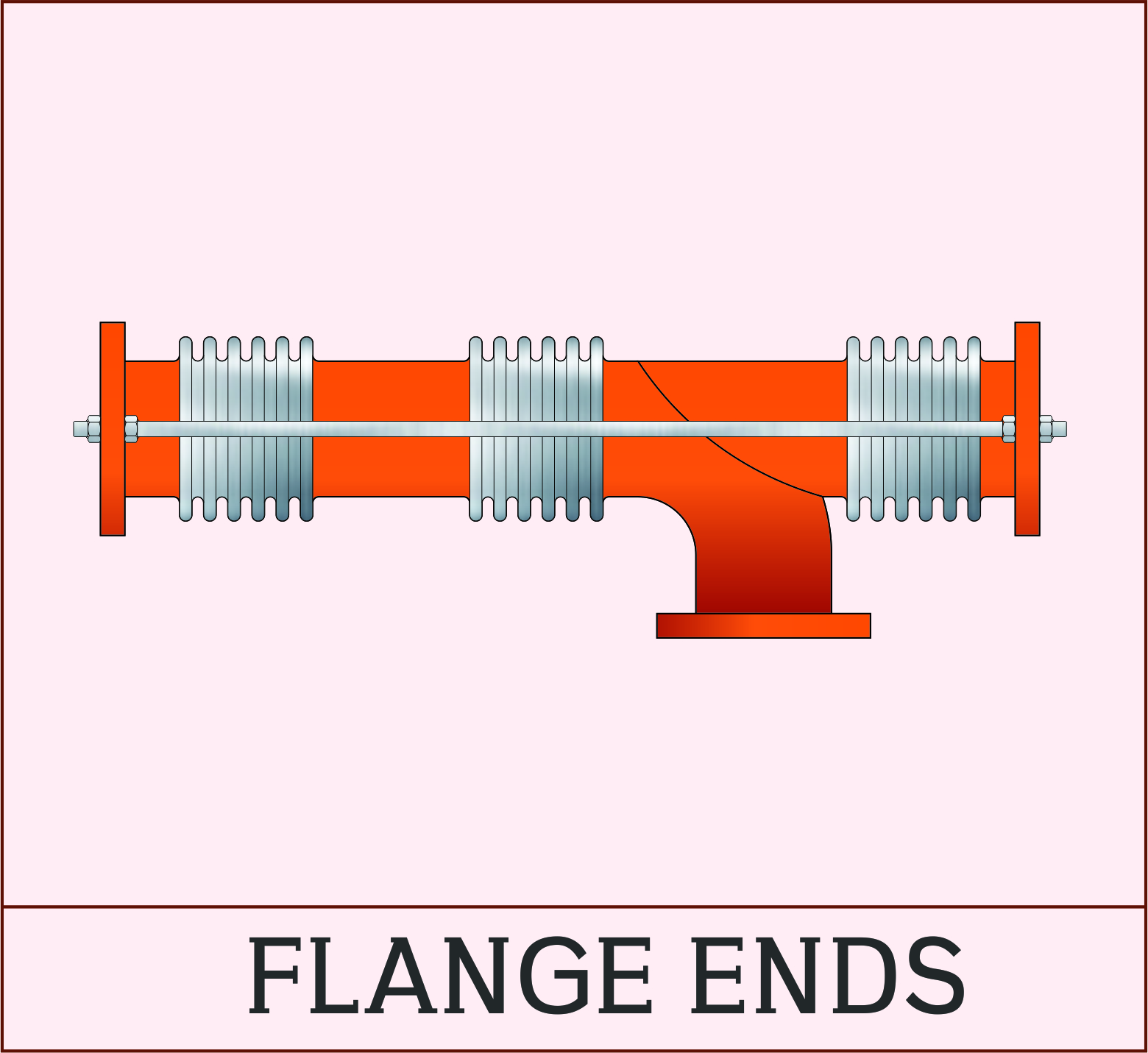

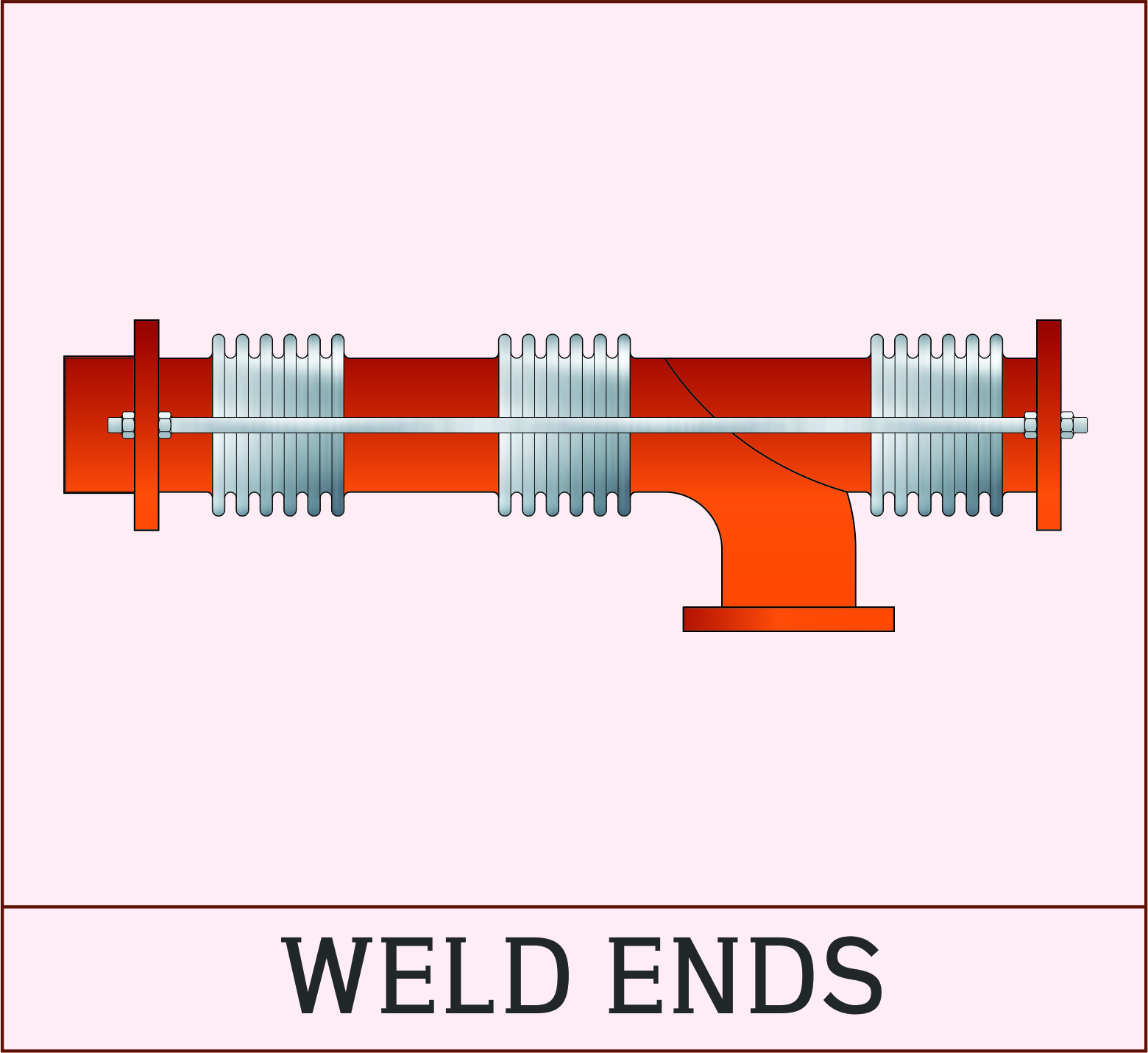

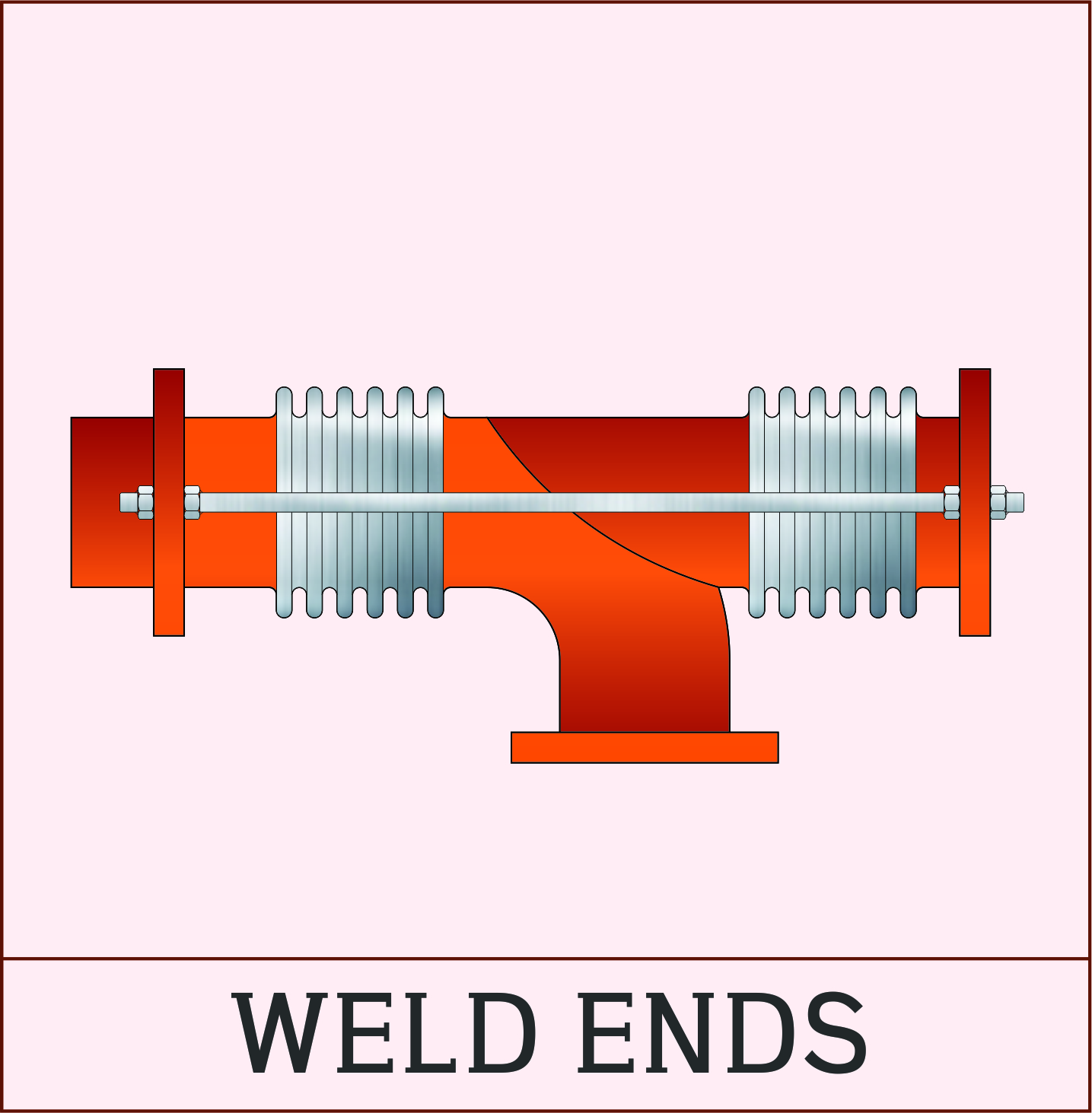

Similar in construction to an Universal Assembly except the tie rods absorb pressure thrust and limit movements to lateral off set and angulation. Large offset movements are possible in a Universal Assembly by increasing the distance between the two bellows.

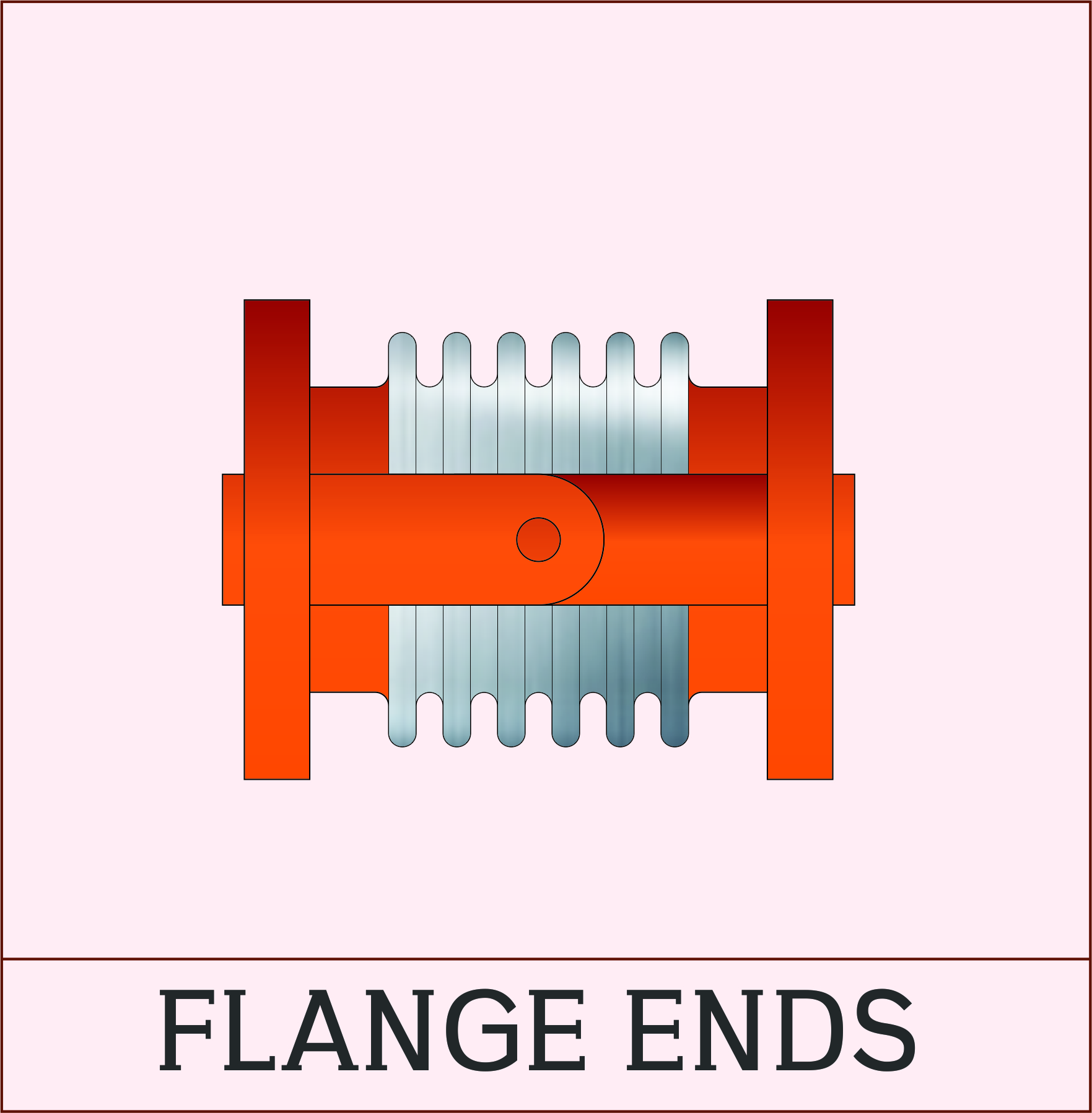

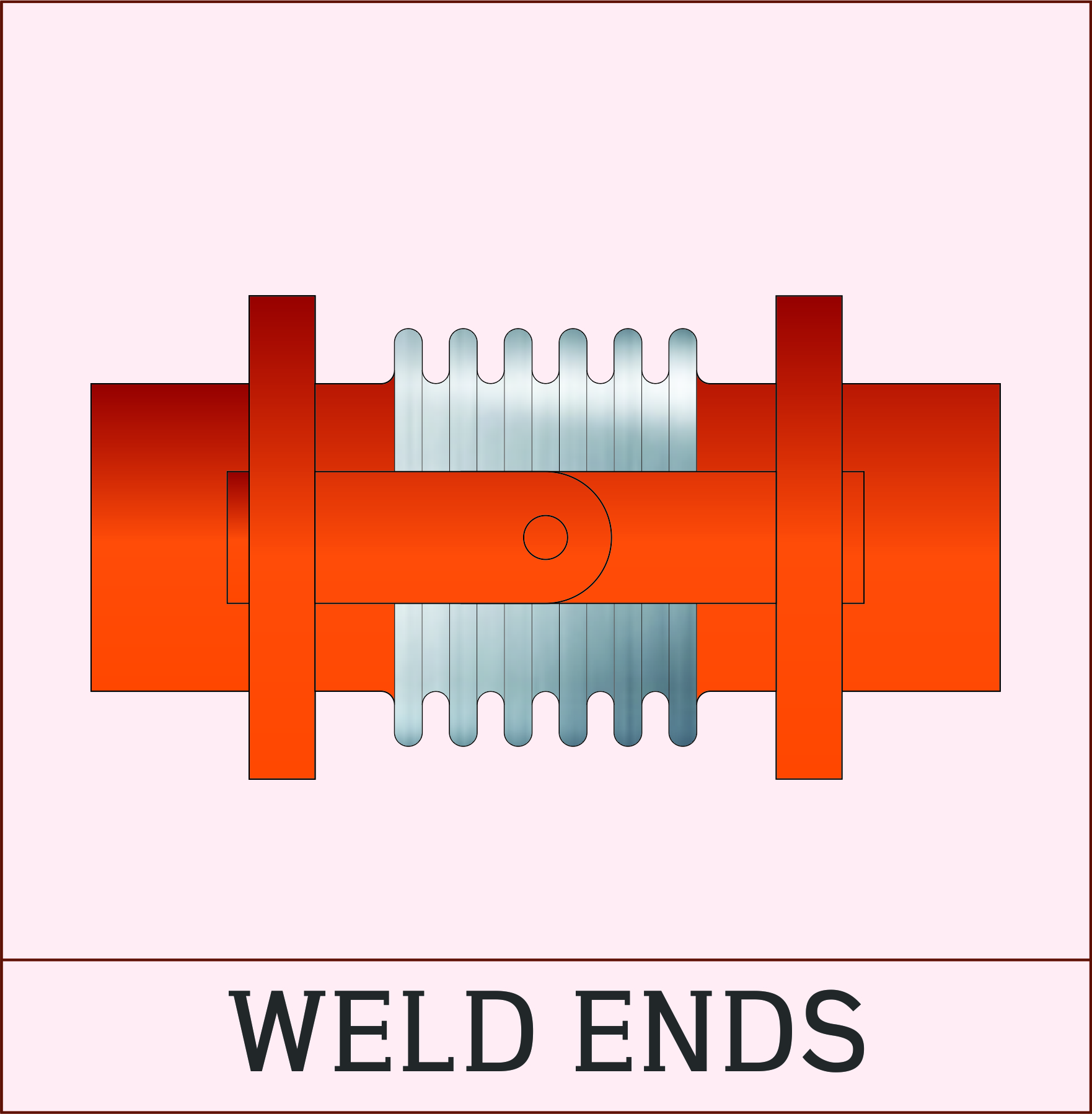

When a Hinged Expansion Joint is used, movement is limited to angulation in one plane. Hinged Assemblies are normally used in sets of two or three to absorb large amounts of expansion in high pressure piping systems. Only low spring forces are transmitted to the equipment. The hinge hardware is designed to carry the pressure thrust of the system. Slotted Hinged, Expansion Joints are a varient of the standard Hinged Expansion Joints that allow axial and angular movement. Be careful! Once Slotted Hinge is introduced torison in the piping system is still resisted but the hinge no longer carries pressure thrust.

The gimbal restraint is designed to absorb system pressure thrust and torsional twist while allowing angulation in any plane. Gimbal Assemblies, When used in pairs or with a single Hinged unit , have the advantage of absorbing movements in multi-planer piping systems.

These assemblies are used in applications where space limitations preclude the use of main anchors. Pressure thrust acting on the line bellows is equalized by the balancing bellows through a system of tie rods or linkages. The only forces transmitted to equipment are low spring forces created by the axial, lateral or angular movements. An elbow must be present.

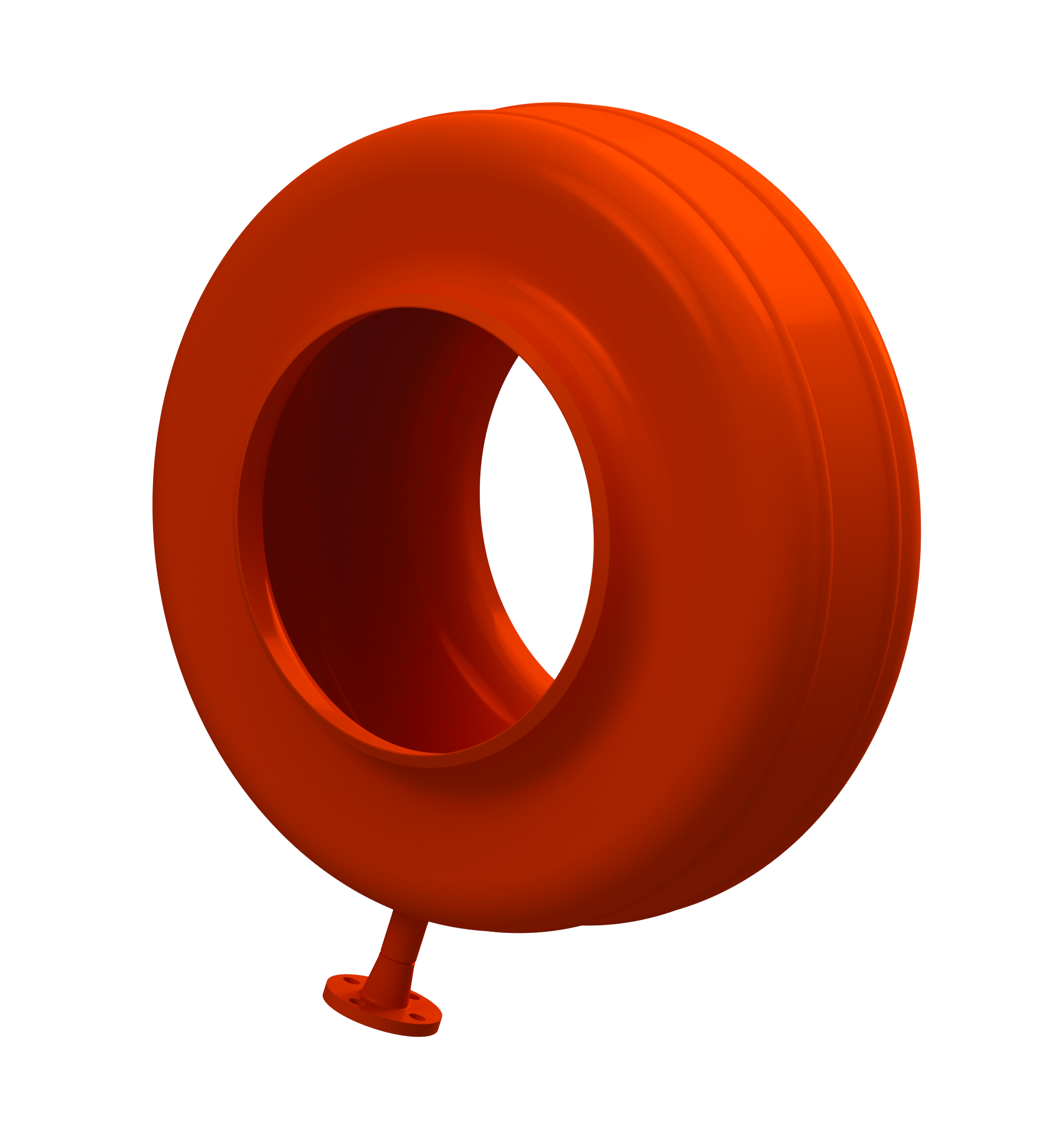

If large amounts of axial movement in a system are needed and the expansion joint must absorb pressure thrust , an Externally Pressurized Pressure Balanced Assembly is the solution. The opposing force balancing theory is similar to the In-Line Pressure Balanced Assembly except the opposing forces are generated from pressure acting on the outside of the bellows.

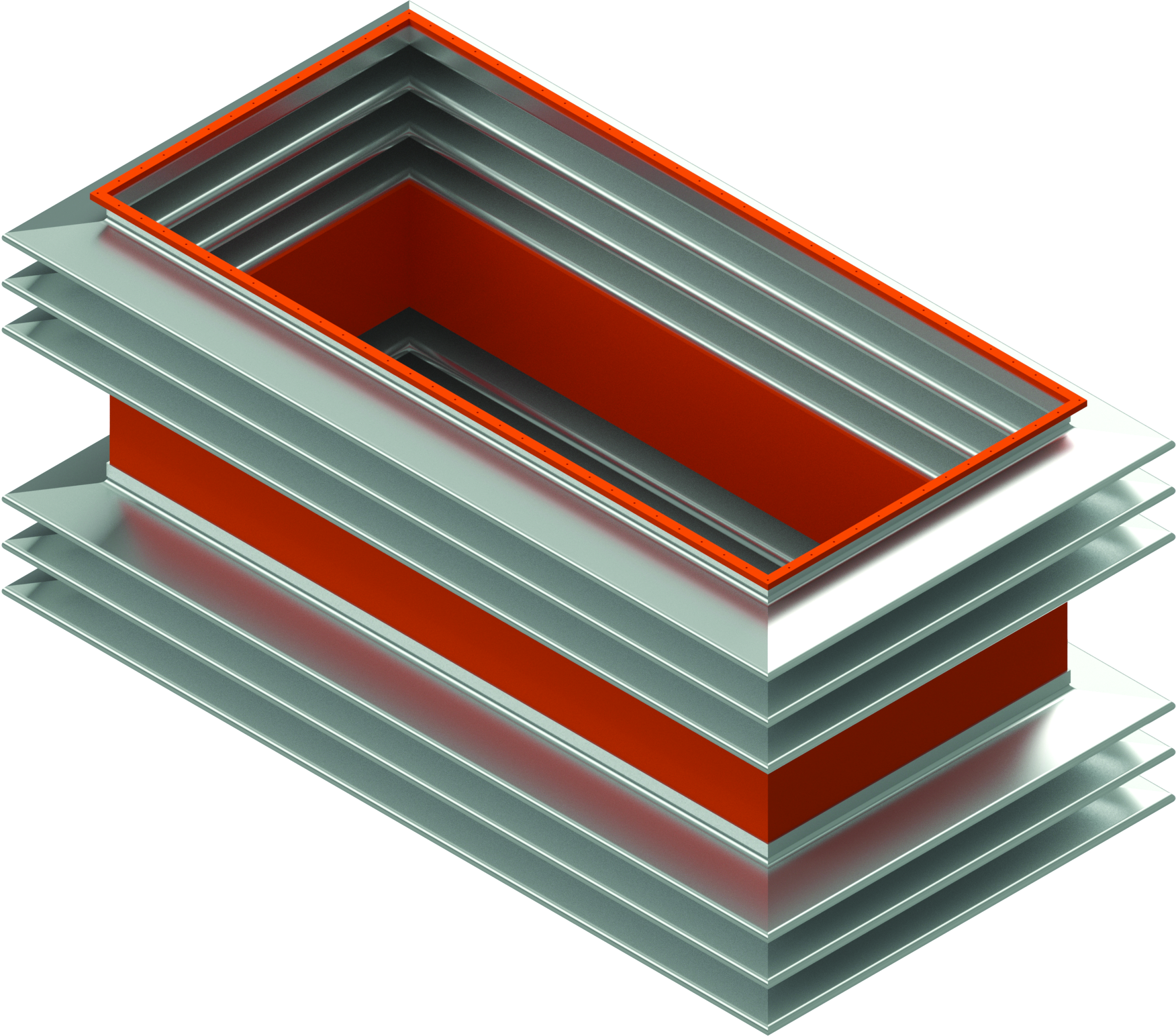

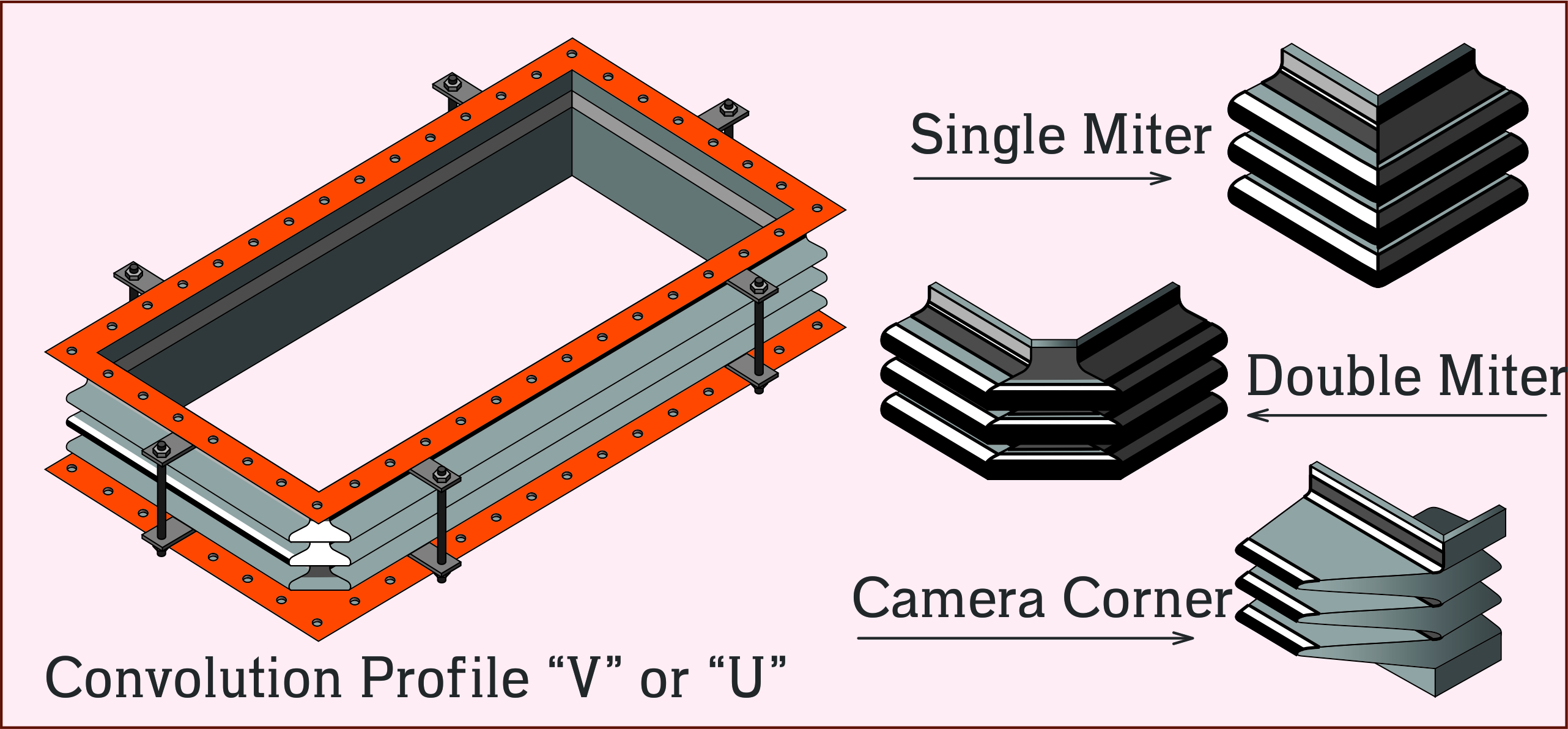

Rectangular metal expansio joints are used for a varitey of application in power plant , petrochemical, refinery, chemical and steel plant industries. Due to the wide range of pressure,temperature, and duct size requirements, each rectangular metal expansion joint is custom-engineered to provide an economical design that will not compromise on the integrity of the entire system.

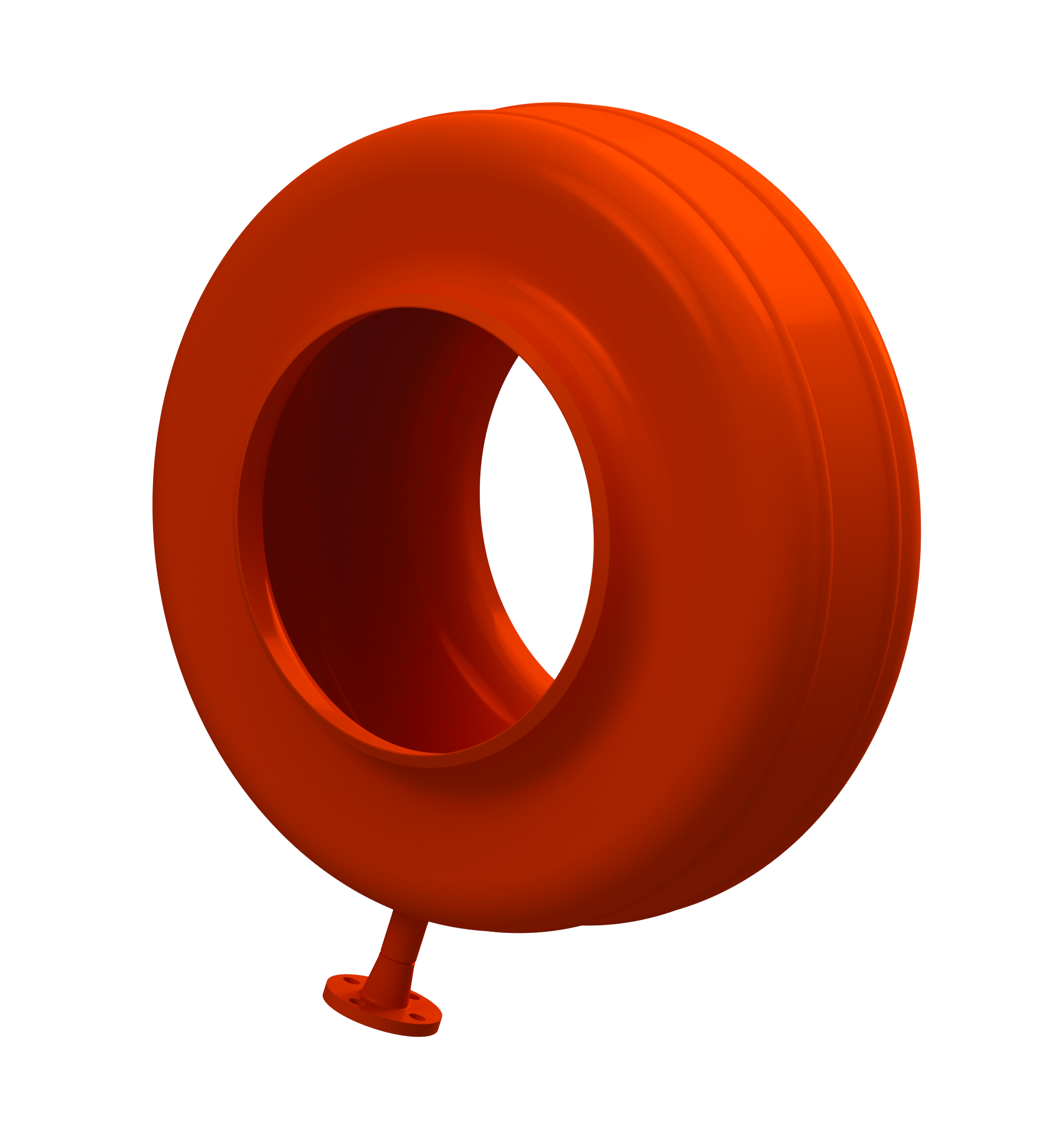

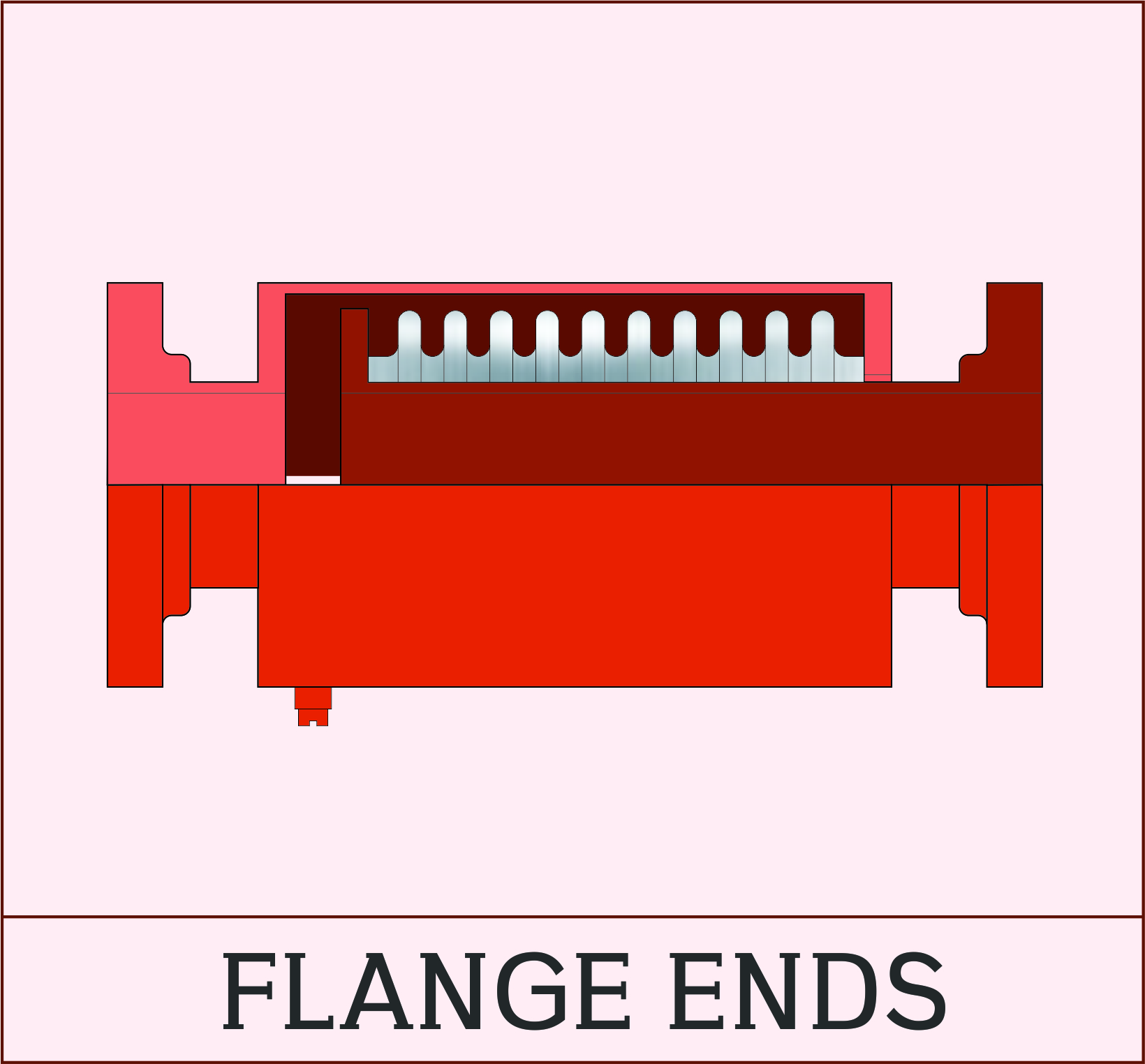

Thick Wall Expansion Joints are used in a Heat Exchangers (specifically fixed tube or floating head variants) and large diameter duct systems where thin Wall Expansion Joints cannot be used.

Fabric Expansion Joints are often used in ducts which carry hot gases at low pressure. The major design parameters are temprature, pressure and flow rates of the media going through the duct. Layers of different fabrics , insulations, and metal foils can be combined to accomodate different temperatures and pressures in the system.